Cartón completamente automático de cuatro colores que hace la máquina

Información básica

Modelo: YD-SYK 1224

Descripción del producto

Modelo NO .: YD-SYK 1224 Grado automático: Automático Tamaño máx. Tamaño de alimentación: 1200X2450mm Min. Procesamiento Tamaño: 320X650mm Máx. Velocidad: 100 Hojas / Min Marca: Qisheng Origen: China Tipo: Carton automático que hace la máquina Ancho del interior de la máquina: 2600mm Área de impresión efectiva: 1200X2200mm Espesor de la placa: 7.2mm Catálogo: Cartón que hace la máquina Especificación: YD-SYK 1224 HS Código: 84414000 YD-SYK 1224 Cartón completamente automático que hace la máquina

YD-SYK 1224 Máquina de impresión de tinta de cuatro colores totalmente automática y de troquelado (ranura)

Detalles técnicos principales:

Para necesidades técnicas, ajuste de la estructura del producto ligeramente sin previo aviso.

(I) Unidad de Alimentación (un grupo)

(II) Unidad de impresión (Cuatro colores)

Para necesidades técnicas, ajuste de la estructura del producto ligeramente sin previo aviso.

(III) Unidad de troquelado (ranurado)

(IV) Unidad de Pila (Una)

Engranaje del conductor

Lista de detalle del motor:

Observaciones: El cliente necesita un compresor de aire autoproclamado.

YD-SYK 1224 Máquina de impresión de tinta de cuatro colores totalmente automática y de troquelado (ranura)

Detalles técnicos principales:

| Item | Unit | 1224 |

| Width of the inside of the machine | Mm | 2600 |

| Max.Feeding Size | Mm | 1200x2450 |

| Effective printing area | Mm | 1200x2200 |

| Min.Processing Size | Mm | 320x650 |

| Thickness of plate | Mm | 7.2 |

| Max.Speed | Sheets/min | 100 |

| Economic Speed | Sheets/min | 80 |

| Main motor power | KW | 22 |

| Total power | KW | 36.34 |

| Chromatically precision | Mm | ±0.5 |

| Die-cutting precision | Mm | ±1.0 |

| Slotting width | Mm | 7 |

| Width of corner cutting | Mm | 50 |

| Slotting precision | Mm | ±1.0 |

| Dimension (mm) | L | 5500 |

| W | 4530 | |

| H | 2000 | |

| Net weight | Kg | 20000 |

(I) Unidad de Alimentación (un grupo)

| Item | Instruction |

| 1.Board On-off |

1Electric control board on-off with alarm bell, ensure safety for workers. 2Transmission shaft with slip clutch, avoid misuse to damage machine. 3Pneumatic interlocker 4Machine main motor start protection device. |

| 2.Frontal roller feeding unit |

1Feeding with air draft, horsepower of fan 7.5kw,air can be adjustable by the camber of cardboard, ensure feeding successfully. 2Up and down pressing adopt air cylinder, quick-moving and save time. 3Adopt adsorption frontal roller feeding unit. 4Lateral board, backboard all use electric-control;The distance between two pre-boards can adjust synchro manual 5Skip feeding unit(based on need to select) 6The counter shows production quantity and current speed |

| 3.Feeding roller |

1The out-diameter of up feeding roller is Φ 124mm 2Solid steel wrap up abrasive rubber with equilibrium regulating. 3The out-diameter of down feeding roller is Φ 155mm, surface with embossing and chromalizing. 4The gap-dial of feeding rollers can be adjusted by manual, adjusting range 0~12mm |

| 4.Automatic Zero unit |

1Feeding unit ,printing unit and slotting unit all electric automatic zero. 2Generic use automatic zero unit, try to print two sheets can be adjusted to correct size, reduce cardboard waste. |

| Item | Instruction |

|

1.Printing roller (Plate roller) |

1Out diameterΦ390.6mm (including plateΦ405mm) 2Steel tube surface with grinding and chrome plating. 3with equilibrium regulating, steady running 4ratchet wheel fixed lapping shaft 5Full plate with plate trough, be applicable for 10mmx3mm 6Handling printing plate, foot-switch electric control normal-reverse running. |

| 2.Pressing and printing roller |

1Out diameter Φ155mm 2Steel tube surface with grinding and chrome plating 3with equilibrium regulating, steady running 4The gap-dial of pressing and printing rollers can be adjusted by manual, adjusting range 0~12mm |

| 3.Feeding up and down roller |

1Up roller:Out diameter Φ96mm thick wall steel tube with four feeding wheels 2Up roller:Out diameter Φ155mm thick wall steel tube, with surface grinding and chrome plating. 3The gap-dial of feeding rollers can be adjusted by manual, adjusting range 0~12mm |

| 4.Steely netted roller |

1Out diameter Φ197mm 2Steel tube with surface grinding, embossing netted and chromalizing. 3with equilibrium regulating, steady running 4screen numbers 200,220,220,250 5act in concert with feeding unit pneumatic automatic lifting device.(Netted roller down moving to touch printing plate when feeding cardboard, netted roller up moving to separate with printing plate when stop feeding cardboard ) 6Netted roller with Kingsbury-type over clutch, easy to ink and cleaning ink quickly |

|

5.Ceramics Netted roller (selection) |

1Out diameter Φ197mm 2Steel tube surface wrap up abrasive rubber with equilibrium regulating 3screen numbers 250,280,300,320 4Long life performance |

| 6.Rubber roller |

1Out diameter Φ190mm 2Steel tube surface wrap up abrasive rubber with equilibrium regulating 3better ink-guide result |

| 7.Phasing unit |

1Planetary type gear structure 2Printing phase adopt PLC electric adjustable,360°.(Running and stop all adjustable) 3Electric adjust lateral direction, the distance is 10mm 4Automatic reset when printing after cleaning printing plate |

| 8.Ink recycling |

1Pneumatic surge pump, ink supply steady, easy to operation and maintenance. 2Ink filter, filter out impurities. 3This machine has alarm without ink. |

| 9.Printing phase fixed device |

1Pneumatic brake unit 2When machine board sundering or phasing, brake unit can prevent board moving, keep intrinsic fixed point. |

(III) Unidad de troquelado (ranurado)

| No. | Item | Functions and technical parameters |

| 1 | Die-cutting control panel |

1.Electric control die-cutting roller phase, axial moving. 2.Have emergency stop button 3.Die-cutting up roller electric control lift 4.Have stopped feeding button, it could control feeding unit, printing unit and die-cutting unit. |

| 2 | Die roller(down) |

1.Adoption high quality steel with fine casting and surface chromeplate treatment. 2.Dynamic balance amendment, increase running stability. 3.Die roller left and right lateral shifting ±10mm, electric adjustment. 4.Die roller circumferential adjustment adopt satellite gear for 360° 5.Die roller with pneumatic lift, easy to operation, reduce die-cutting times, life-saving |

| 3 | Rubber- cushion roller(up) |

1.Adoption high quality steel with fine casting and surface chromeplate treatment. 2.Dynamic balance amendment, increase running stability. 3.Electric tension, lateral shifting ±35mm 4.Be equipped with Taiwan YoLi rubber, easy to change and economy. |

| 4 | Phase adjustment device (down roller) |

1.Adopt satellite gear to phase adjustment. 2.Die-cutting phase adopt electric digital 360°to adjust (Running and stop).Adopt PLC control, touch screen control. 3.Die-cutting roller axial translation adopt electric adjustment, numeric control show adjustments±10mm,easy to link plate. |

| 5 | Speed difference compensation device | This function can automatic compensate the line speed of cushion roller after amending, keep die-cutting precision.By the diameter of cushion become small after amending, its line speed become lower, this device can make their speed to the same, then keep every carton for the same size absolutely. |

| 6 | Die roller Pneumatic lift | Die roller has pneumatic lift device, easy to die-cutting;Reduce times, then life-saving. |

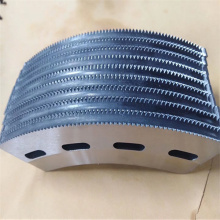

| 7 | Be equipped with four sets steel tool shelf. | Besides traditional die-cutting, it has slotting function.To process plain carton for slotting and corner-cutting.Four knives synchro control, sideslip by hand. |

| Item | Instruction |

| 1, Receive paper arm |

1select manual or automatic to operate 2driving belt can be individual adjusted tightness and unacted on their length, easy to adjust, flexible and fast. |

| 2.Machine lift |

1 power chain driving 2 pile height is 1600mm 3 Machine lift motor has brake function to keep fixed position and not glide without control instructions. 4 Add safety protection device, bed lift in the manipulation to ensure operator safety. 5 Plane climbing belt wrinkles, prevent the cardboard slide |

| 3.Receive paper baffle |

1pneumatic control receiving paper baffle, photoelectric control cardboard piling height 2the position of back baffle based on cardboard length by manual adjusted. |

| Item | Instruction |

| 1/ Main driver gear | 1Material:Steel alloy with quenching and tempering treatment after grinding process. |

| 2/ CAPT-LOCKS union link | 1Adopting CAPT-LOCKS union link, which can make axis connect with gear seamlessly, when torque without gap, easy to install and maintain and can keep high precision for long time to keep printing quality. |

| Name | Origin | Specification | Quantity |

| I Feeding Unit | |||

| 1 main motor | Shanghai | 22kw | 1 |

| 2 board open and shut | Shanghai | 1.5kw 1/60 reducing motor | 1 |

| 3 side shield adjustment | Shanghai | 0.18kw 1/60 reducing motor | 2 |

| 4 back shield adjustment | Shanghai | 0.18kw 1/60 reducing motor | 1 |

| 5 adsorption fan motor | Shanghai | 7.5kw | 1 |

| II Printing Unit | |||

| 1 Phasing adjustment | Changzhou | 0.18kw 1/30 reducing motor | 1/color 4sets |

| 2 rubber roll free play | Taiwan | 0.75kw 1/40 reducing motor | 1/color 4sets |

| 3 roll lateral adjustment | Jiangsu | 0.18kw 1/60 reducing motor | 1/color 4sets |

| 4 netted roll | Jiangsu |

|

|

| 5 rubber roll | Shanghai |

|

|

| III Die-cutting Unit | |||

| 1 phasing adjustment | Zhejiang | 0.18kw 1/30 reducing motor | 1 |

| 2tool roll sideslip | Shanghai | 0.18kw 1/60 | 1 |

| 3die-cutting amending roll | Shanghai | 0.2kw 1/200 | 1 |

| 4die-cutting rubber roll lift | Shanghai | 0.37kw 1/300 | 1 |

| IV others | |||

| 1 bearing | Haerbin | All |

|

| 2 electrical appliance |

Snider, Siemens Chint |

All |

|

| 3 PLC transducer | Taiwan Taida | All |

|

| 4 CAPT-LOCKS union link | Shanghai | All |

|

| 5 pneumatic one-way surge pump | Fujian FuDing | All |

|

Grupos de Producto : Máquina de corte y troquelado de impresión

Premium Related Products

Otros productos

Productos hot

Máquina para fabricar cubiertas de zapatos (BF-31PE)Duck Bill Mask Making Machine (BF-21)Máquina de fabricación de cubiertas de baño por ultrasonidosCup Mask Earloop Welding Machine de 2 puntosMáscara plegable completamente automática que hace la máquina 9001/9002 máquina de la máscaraMáscara facial médica no tejida ultrasónica automática que hace la máquina de la máquina interna de Earloop 2Rueda de pre-prensado tipo cartucho Qisheng CartonAbsorción Línea de Producción de Carbón Acanalado Simple FacerPE máquina de embalaje de la correaMáquina de plegado y troqueladoZh-X1224 automática de cuatro colores de impresión y ranurado de la máquinaWj-150-1600 Línea de producción de cartón corrugado de 5 capasCaja de forma especial que hace la máquinaMáquina de corte rotativa automática de alimentación de papel (879)Empaquetado de impresión y ranurado Die-Cutting Machine (GYMK)Impresión de Gymk que ranura la máquina de cartón de troquelado